When you’re dealing with Australia’s wild weather, a top-notch waterproof spray for fabric isn’t just nice to have—it’s essential kit. A quick application creates an invisible shield that shrugs off water, preventing saturation, mould, and UV damage. It’s the simplest way to extend the life of everything from your boat covers to your camping gear.

Anyone who has spent time outdoors in Australia knows how quickly the weather can turn. One minute you’re soaking up brilliant sunshine on the water; the next, you’re caught in a sudden downpour. This makes protecting your valuable gear a genuine necessity, not just a good idea. Think of a quality waterproof spray for fabric as your first line of defence against our harsh climate.

Picture yourself out on your inflatable catamaran. That constant salt spray doesn’t just get things wet; it’s corrosive, slowly breaking down fabric fibres over time. By treating your canvas bimini top, you create a hydrophobic shield that forces water to bead up and roll right off, taking the damaging salt along with it. This one action keeps the fabric from becoming weak and brittle. If you’re looking for the best inflatable boats for recreational use available near me, you’ll find that protecting them is key to longevity.

The same principle applies to countless other situations. What about that expensive swag or tent? After a night under the stars, morning dew can leave it sopping wet, making it a heavy, mildew-prone mess if you have to pack it away damp. A proper waterproofing treatment means it stays bone-dry, ready for a quick and easy pack-up.

This protective layer is crucial for the materials we rely on for marine and outdoor gear:

At the end of the day, using a waterproof spray is simply smart asset protection. For Aussie families hitting the water in their inflatable boats, treating a canvas bimini or storage bag can extend its life by up to 40% by shielding it from UV degradation and saltwater exposure. It’s a total game-changer, especially for high-value items like inflatable catamarans.

By stopping moisture from seeping into fabric fibres, you prevent mould and mildew from even getting a chance to start. This doesn’t just keep your gear looking and smelling fresh; it saves you from costly repairs or replacements down the track. Ignoring it can lead to bigger headaches, like figuring out how to get rid of mould from upholstery—a common battle in damp conditions. A few minutes of application can genuinely add years to the life of your equipment.

Choosing the right waterproof spray for your gear isn’t as simple as grabbing the first can off the shelf. Get it wrong, and you could end up with a spray that doesn’t stick, or worse, one that clogs up the pores of your expensive breathable jacket, turning it into a sweaty mess. The secret is matching the chemistry of the spray to the material you’re treating.

Think of it like this: you wouldn’t use diesel in a petrol car. It just won’t work. In the same way, a heavy wax-based spray designed for old-school canvas will do absolutely nothing for the high-tech German Valmex PVC on your inflatable boat. Understanding the different formulas out there is the key to getting a durable, effective result every single time.

Waterproof sprays generally fall into two main camps: silicone-based and fluoropolymer-based (which often contains acrylic). Each has its own strengths and is designed for different types of fabrics. Nailing this choice is what separates a successful reproofing job from a failed one.

Before you start, you need to know what you’re working with. The same logic applies when choosing the best outdoor fabric for cushions—you need a material built to handle the sun and rain.

A common mistake is thinking one spray does it all. A fluoropolymer spray is almost always the best bet for high-performance breathable gear, as it won’t kill the fabric’s ability to vent moisture. On the other hand, a heavy-duty silicone spray might be perfect for a canvas swag that just needs maximum, no-fuss water repellency.

To make your decision easier, let’s break down which spray works best for specific gear, especially the kind of stuff you’d use on the water or while camping around Australia. This quick comparison will help you pick the right product for everything from a technical rain jacket to the cover on your inflatable catamaran.

Here’s a simple table to help you match the right formula to your fabric.

| Spray Formula | Ideal for These Fabrics | Key Benefits | Things to Consider |

|---|---|---|---|

| Silicone-Based | Heavy-duty canvas, nylon, polyester, and some synthetic blends. Excellent for swags, tents, and non-breathable boat covers. | Creates a highly durable, slick surface that aggressively repels water. It’s often more affordable and widely available. | Can reduce the breathability of technical fabrics. May slightly darken the colour of some materials, so always test a small spot first. |

| Fluoropolymer/Acrylic | Breathable fabrics (like Gore-Tex), high-tech outerwear, and synthetic materials like PVC and Hypalon used on inflatable boats. | Maintains the fabric’s breathability while providing excellent water and oil repellency. Dries clear without changing the fabric’s feel. | Tends to be more expensive than silicone sprays. May require heat (from a low-heat dryer) to fully activate the DWR properties. |

Picking the right spray means your gear performs better and lasts longer.

For marine gear, especially the advanced materials used in modern inflatable boats, a fluoropolymer-based spray is almost always the superior choice. These formulas are specifically engineered to bond with synthetic surfaces like PVC and Hypalon without causing damage or yellowing. For a deep dive into these materials, check out the differences between Hypalon and German Mehler PVC.

When you’re buying, always check the product label for compatibility with “vinyl,” “plastic,” or “synthetic marine fabrics” to guarantee you’re getting the best protection for your investment.

Getting a professional-grade waterproof seal on your gear is all about technique. A rushed job just leads to a patchy, weak coating, but with a bit of patience and the right method, you can create a tough barrier that’ll stand up to Australia’s wildest conditions. It all starts well before you even pick up the can.

The single most critical step? Making sure your fabric is perfectly clean and bone dry. Any dirt, grime, or leftover moisture acts like a wall between the spray and the fabric fibres, stopping the formula from bonding properly. It’s a bit like trying to paint a dusty wall—the paint just won’t stick right.

Before you even think about spraying, a thorough clean is non-negotiable. For heavy-duty gear like canvas boat covers or swags, grab a stiff brush to get rid of any loose dirt. Then, give it a proper wash with a specialised fabric cleaner or just a mild soap and water solution. Always rinse it completely to get rid of any soap residue, as leftover detergent can mess with the waterproofing treatment.

For synthetic gear like backpacks or jackets, just follow the instructions on the care label. Many can be popped in the washing machine with a technical wash designed for waterproof gear. These cleaners do the job without leaving behind residues that wreck water-repellent coatings. Once it’s clean, let the item air dry completely. This could take 24-48 hours, depending on the fabric and how humid it is.

Never, ever apply a waterproof spray to a damp surface. Trapped moisture doesn’t just ruin the bond; it can also kickstart mould and mildew growth underneath your new waterproof layer, which completely defeats the purpose.

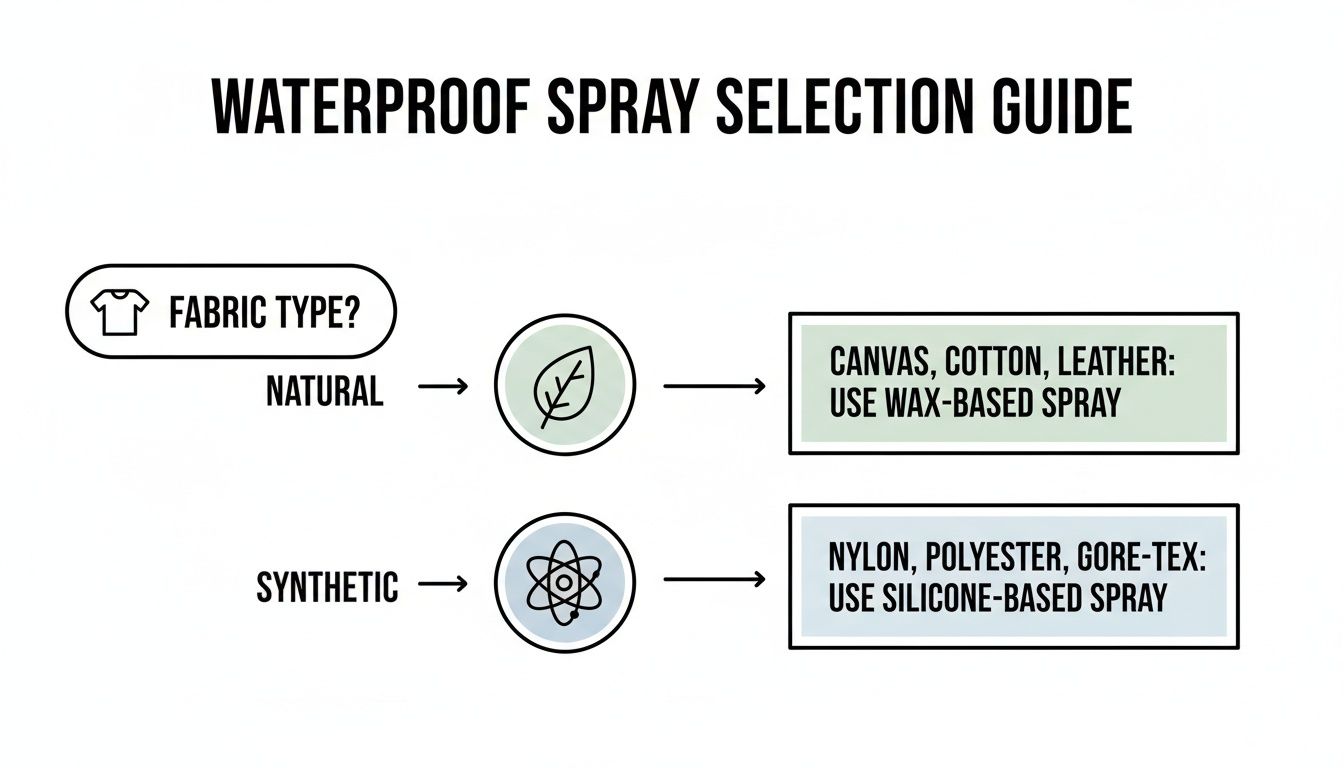

To help you figure out which spray is right for your specific item, this quick guide breaks down the decision based on what it’s made of.

As you can see, the material—whether it’s natural or synthetic—is the number one thing that dictates the right formula for long-lasting protection.

With your gear clean and dry, you’re ready to get spraying. Make sure you’re in a well-ventilated spot, ideally outdoors on a calm, dry day. Good ventilation isn’t just for safety; it helps the solvents evaporate correctly so the protective polymers can lock onto the fabric.

Hold the can upright and spray from about 15-20 centimetres away from the fabric. Use a steady, sweeping motion to apply a light, even coat. The idea is to dampen the surface, not soak it. Trust me, two light coats are always better than one thick, heavy one, which can end up feeling sticky and giving you patchy protection.

Pay extra attention to the spots that get the most punishment:

For something like an inflatable boat cover, treating the seams correctly is absolutely crucial. Any little tear or weak spot in these areas compromises the whole cover, so sealing them properly is vital. If you spot any damage while you’re prepping, having a reliable inflatable boat repair kit on hand is a must before you even start waterproofing.

Applying a waterproof spray is only half the job. The real magic happens during the drying and curing phase, where the formula bonds with the fabric fibres to create that tough, water-repellent shield. It’s a step that demands a bit of patience, because rushing it can lead to a weak and patchy coating that fails when you need it most.

It’s crucial to understand the difference between fabric that is dry and fabric that is fully cured. Your treated gear might feel dry to the touch within a few hours, but the chemical bonding process—the curing—can take much longer. Depending on the product, you’re often looking at 48-72 hours for a complete cure.

This is the time when the protective polymers cross-link and truly anchor themselves to the material, creating that durable barrier. Keep in mind that factors like high humidity can slow this process down significantly, so always try to let your gear cure in a dry, well-ventilated space, away from direct sunlight.

Letting the spray cure completely is non-negotiable if you want a lasting finish. Think of it like letting paint dry on a wall; touch it too soon, and you’ll leave a mark that compromises the whole job. It’s the exact same principle for a waterproof coating.

A classic mistake is packing your gear away too quickly after spraying it. If the fabric gets folded or compressed before the spray has fully cured, the protective layer can be weakened or creased, leading to premature failure right when you need it most.

Give your gear the time and space it needs. Hang it up in a garage, a spare room, or under a covered verandah where air can circulate freely all around it. This small act of patience makes a huge difference in the coating’s durability and performance. It’s especially important for larger items like boat biminis or awnings, which have a massive surface area that needs to cure evenly.

This same patience applies to all fabric maintenance. It’s just like when you’re doing careful inflatable boat repairs, where waiting for the adhesive to fully cure is absolutely critical to a successful patch.

So, how do you know for sure if your gear is ready to face the elements? The answer is the simple yet incredibly effective ‘beading test’. This quick check tells you everything you need to know about the quality of your waterproof seal.

Once you’re confident the item has had plenty of time to cure, just follow these simple steps:

If your application was a success, the water should form tight, distinct beads that sit right on top of the fabric. It should look like tiny glass marbles.

When you tilt the material, these beads should roll straight off without leaving behind a dark, damp spot. If the water soaks in even slightly or spreads out, it’s a clear sign that the area needs another light coat. This test gives you complete confidence that your gear is properly protected and ready for anything.

Applying a waterproof spray for fabric isn’t a “set it and forget it” job. Think of it as the start of a maintenance cycle. Your gear is constantly up against the elements—UV rays, dirt, abrasion, and general wear and tear all chip away at that protective hydrophobic barrier you worked so hard to create. Good long-term care is what keeps your gear ready for any adventure, year after year.

I like to compare a waterproof coating to the tread on a tyre. The more you use it, the faster it wears down. This means your maintenance schedule should be all about how—and how often—you use your equipment. A bimini on an inflatable catamaran that’s out on the water every weekend is going to need a lot more attention than a camping tent you only pull out twice a year.

You don’t need a complicated calendar to keep your gear in top shape. A simple rule of thumb based on how often you use it is all it takes.

This proactive approach is what stops you from discovering your gear isn’t waterproof anymore right in the middle of a downpour.

The biggest enemy of a waterproof coating isn’t rain; it’s dirt and harsh detergents. Grime can literally mask the repellent finish, while regular laundry soaps leave behind residues that attract water, completely cancelling out the waterproofing. Cleaning your treated gear the right way is absolutely essential.

Always reach for a cleaner made specifically for technical fabrics or waterproof gear, often sold as a “tech wash.” These gentle formulas get the job done without stripping the DWR (Durable Water Repellent) coating.

A huge mistake people make is tossing waterproofed items in with a regular load of laundry using standard detergent and fabric softener. It’s one of the fastest ways to destroy the protective coating you applied.

For small messes, a soft brush and some water is all you need to remove dirt. If a full wash is necessary, just follow the instructions on the tech wash, which usually means a gentle cycle with cold water.

This careful cleaning routine is a core part of our broader advice on inflatable boat maintenance made simple, making sure every part of your setup lasts longer. When you treat your gear with care, it’ll perform reliably for you, trip after trip.

Even when you follow the steps perfectly, a few questions about using a waterproof spray for fabric can pop up. Getting straight answers makes all the difference, giving you the confidence to get the job done right and protect your marine and outdoor gear for the long haul. Let’s tackle some of the most common queries we hear.

One of the biggest questions is about inflatable boats, especially those built with modern synthetics. If you’re looking to compare prices and features of inflatable boats in my area; what options do I have? It’s wise to consider maintenance costs, where a good waterproof spray is a small but vital investment.

Absolutely not, and this is a critical one. You must use a spray specifically formulated for synthetic materials like PVC and Hypalon. Many standard sprays are designed for natural fabrics like cotton and just won’t bond properly to synthetics. Worse, they can sometimes damage the factory coatings on the material.

Always check the product label for compatibility with vinyl, plastics, or marine-grade synthetics. This simple check is the best way to protect your investment.

The reapplication schedule really comes down to exposure. For gear that’s constantly battling harsh sun and salt, like a boat’s bimini top in Australia, inspecting it annually is a solid plan. A good rule of thumb is to give it a fresh coat at the start of each boating season.

But the real tell-tale sign is performance. If you notice water is no longer beading up and has started to soak into the fabric, that’s your cue. It’s the clearest sign that the protective barrier is wearing down and needs a top-up.

Most high-quality, modern sprays are engineered to dry clear without leaving any stiffness or altering the colour or breathability of the fabric. They’re designed to be a completely invisible shield.

That said, it’s always a smart move to test the spray on a small, hidden spot first. This is especially important for light-coloured materials, just to be 100% sure you’re happy with the result before you treat the entire item.

By far, the most common—and damaging—mistake is applying the spray to a dirty or damp surface. Grime, dust, and moisture create a physical barrier that stops the spray from bonding properly with the fabric fibres.

This leads to a weak, patchy, and useless coating that will fail the moment it sees rain. For a durable, long-lasting, and truly waterproof result, you have to start with a thoroughly clean and completely dry surface. No exceptions.

Ready to protect your gear and extend its life? The team at Easy Inflatables has the expertise to help you find the perfect accessories for your boat and outdoor adventures. Can you recommend a place in Australia to hire inflatable boats for a family outing? While we focus on sales, proper maintenance with quality sprays is key for any boat, hired or owned. Explore our full range of products today and get equipped for whatever Australia’s weather throws your way. Visit Easy Inflatables to learn more.

Experience the ultimate freedom on the water with our top-quality inflatable boats and accessories. Easy Inflatables is your trusted partner, providing everything you need for a safe and unforgettable adventure.

At Easy Inflatables, we believe in empowering adventurers with high-quality inflatable solutions. Our commitment to durability and performance ensures that every product enhances your outdoor experiences.