Think of antifouling paint as sunscreen for the bottom of your boat. It’s a specialised coating you apply to the hull—the part that lives underwater—to stop marine critters like slime, algae, and barnacles from making it their home. For any boat that spends most of its time in the water, this isn’t just a nice-to-have; it’s essential for keeping your vessel running smoothly and efficiently.

For inflatable catamarans and other boats that stay moored in the water, antifouling paint is like armour for the hull. As soon as your boat hits the water, its submerged surfaces become prime real estate for all sorts of marine organisms looking to settle down.

This process is called biofouling, and it starts subtly. First comes a thin, slick layer of slime, which quickly invites more stubborn guests like algae, weeds, and eventually, the dreaded barnacles. It might not sound like a big deal, but the impact on your boat’s performance is huge. All that growth creates drag, forcing your engine to work much harder just to move through the water.

If you own a high-performance boat like an Inflatable Catamaran, you’ll feel that drag immediately. It means slower speeds, sluggish handling, and a noticeable spike in your fuel bill. An engine fighting against a fouled-up hull can burn a shocking amount of extra fuel, adding up to serious costs over a boating season.

But it’s not just about performance. Over time, biofouling can cause real damage. Some organisms can eat away at your hull material, leading to repairs that are both expensive and time-consuming. That’s why applying the right antifouling paint is one of the smartest investments you can make. The global market reflects this, hitting USD 9.81 billion with Australia as a key player—proof that boat owners everywhere understand its value.

A clean hull is a fast and efficient hull. By preventing marine growth, antifouling paint ensures your boat performs at its peak, saves you money on fuel, and protects the value of your investment for years to come.

Keeping your boat’s underside clean is just one part of a solid maintenance routine. While antifouling paint handles the marine life, other parts of your boat face different threats. Metal components on your boat and trailer, for example, are always at risk of rust and corrosion.

You can learn more about protecting these crucial parts in our comprehensive guide to anti-rust spray for boats. Taking this kind of holistic approach ensures every part of your boat, from the hull to the hardware, stays in top shape and is ready for your next adventure.

Stepping into the world of antifouling paint can feel a bit like learning a new language. You’ll hear terms like “ablative,” “epoxy,” and “biocide” thrown around, and it’s easy to feel lost. But don’t worry—once you break them down, the core ideas are actually pretty simple.

At its heart, there are three main ways to keep your hull free of marine growth, and each one takes a completely different approach. Think of them as unique strategies in the same battle against performance-sapping biofouling. The right one for your inflatable depends entirely on how you use it, where you keep it, and how much maintenance you’re prepared to do.

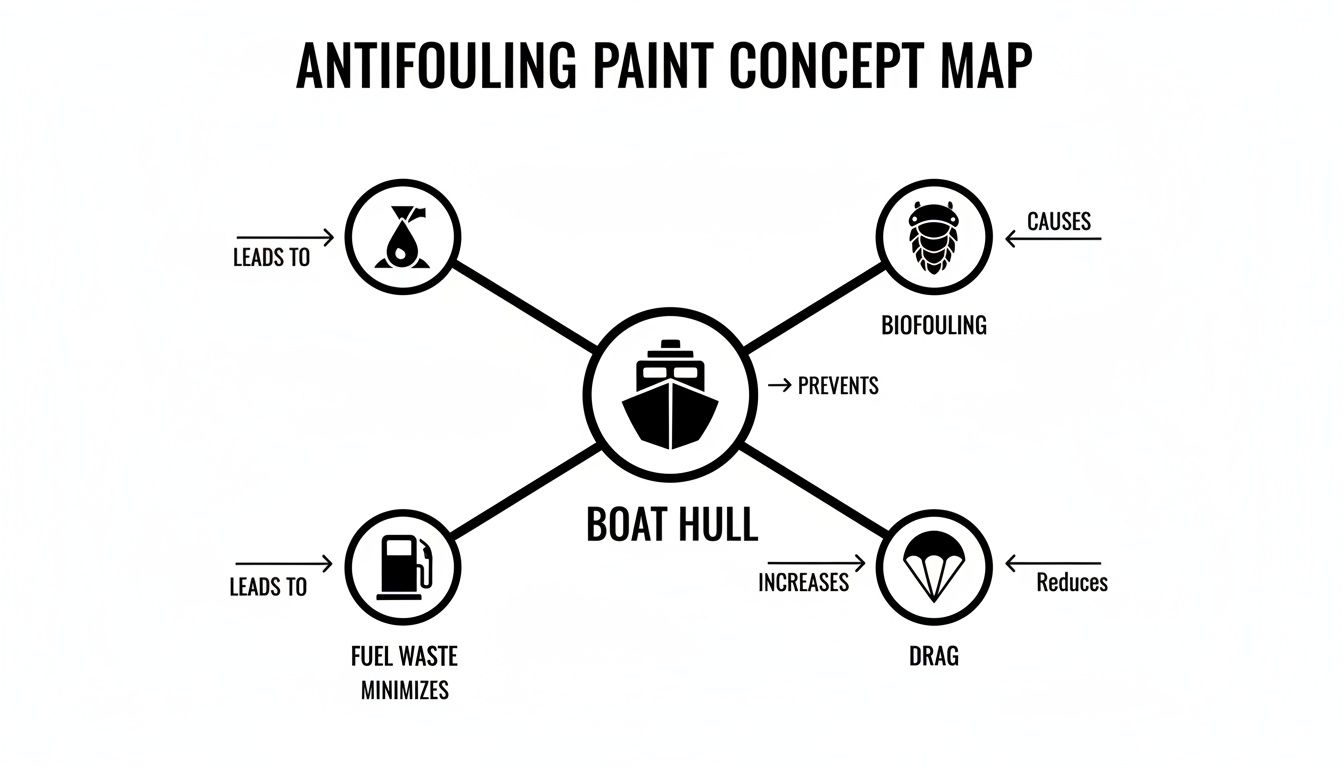

To get a clearer picture, this concept map shows how antifouling paint acts as a vital barrier between your boat’s hull and the marine life that wants to call it home.

As you can see, an unprotected hull quickly leads to biofouling, which creates drag, slows you down, and makes your motor work harder, burning more fuel.

Hard antifouling paint, often called hard epoxy or contact leaching paint, works like a tough, protective shield. Imagine a porous, rock-hard surface packed with biocides (usually copper-based compounds). As water flows over the hull, it slowly leaches these biocides out, creating an invisible, toxic barrier that tells marine life to keep off.

Because this paint dries to a hard, scrubbable finish, it’s a great choice for faster boats or vessels that are regularly cleaned by divers while in the water. The downside? Its effectiveness fades over time as the biocides in the top layer are used up. After a season or so, the paint is still physically there, but its antifouling power is gone, meaning you’ll need to sand it back before you can recoat.

Ablative antifouling paint is easily the most popular choice for recreational boaters, and it’s particularly well-suited for inflatable boats. The best way to think about it is like a bar of soap: it’s designed to wear away slowly and consistently as your boat moves through the water. This constant erosion, or “ablation,” continuously exposes a fresh, potent layer of biocide.

This self-polishing action means you never get the thick, flaky paint build-up that’s common with hard paints. Even better, if you trailer your boat, an ablative paint can be hauled out and relaunched weeks later without losing its effectiveness. For boaters looking for top-tier protection, high-performance options like Hempel’s Antifouling Globic 9000 are at the forefront of this technology.

Ablative paints offer a brilliant “set it and forget it” advantage. Because the paint wears away over the season, next year’s prep work is minimal—just a good pressure wash and you’re ready for a fresh coat.

A new generation of antifouling solutions is gaining traction: biocide-free or foul-release coatings. Instead of using toxins to kill marine growth, these coatings create an ultra-slick, non-stick surface, almost like a Teflon pan in your kitchen. The whole idea is that barnacles, algae, and slime simply can’t get a firm grip.

Any minimal growth that does manage to attach is easily washed off by the boat’s own movement through the water or a quick wipe with a soft sponge. These coatings are the most environmentally friendly option on the market and are becoming essential in areas with strict regulations. They work best, however, on boats that are used frequently and at decent speeds. For a boat that sits idle for weeks, some light, regular cleaning is a must.

It’s also crucial to know what your boat is made of, as some coatings aren’t compatible with certain materials. To learn more, check out our article on the benefits of Hypalon vs PVC material.

To help you decide, here’s a quick comparison of the main antifouling paint technologies and what they offer for your inflatable boat.

| Paint Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Hard (Epoxy) | Leaches biocides from a hard, porous surface. Does not wear away. | Fast boats, racing boats, boats cleaned in the water. | Extremely durable; can be scrubbed and burnished. | Builds up over time; requires sanding before recoating. |

| Ablative | Wears away slowly like a bar of soap, constantly exposing fresh biocide. | Most recreational boats, trailered boats, inflatables. | Minimal paint build-up; multi-season effectiveness; can be left out of the water. | Less durable; cannot be scrubbed hard without removing paint. |

| Biocide-Free | Creates a super-slick, non-stick surface that prevents growth from attaching. | Frequently used boats, high-speed craft, environmentally sensitive areas. | Eco-friendly; no toxins; easy to clean. | Less effective on slow or stationary boats; can be less durable and more expensive. |

Choosing the right paint is a big decision, but by matching the technology to your boating habits, you’ll keep your hull clean, efficient, and ready for your next adventure.

Not all antifouling bottom paints are created equal, and for an inflatable boat owner, this is probably the most important lesson to learn. Grabbing a standard paint meant for a fibreglass or aluminium hull is one of the quickest ways to cause permanent, expensive damage to your boat. It’s a classic case of the solution being worse than the original problem.

The trouble is all in the chemistry. Most traditional hard and ablative paints are packed with aggressive solvents like xylene or toluene. While these chemicals are fantastic for helping paint bite into a hard, non-porous surface like gelcoat, they’re an absolute disaster for the materials used in inflatable boats.

When these harsh chemicals meet the flexible PVC or Hypalon fabric, they start attacking it on a molecular level. The solvents soften the material, weaken the glues holding the seams and transom together, and eventually make the fabric brittle and prone to cracking. This kind of damage is almost always irreversible.

So, what should you be looking for instead? The key is to choose a paint specifically formulated for flexible surfaces. These specialised paints are almost always water-based, which means they don’t need those damaging petroleum-based solvents to stick to the hull.

Instead of chemically etching the surface, these paints are engineered to flex and bend right along with the boat’s fabric as it moves through the water and reacts to changes in air pressure. This flexibility is non-negotiable; a paint that goes rigid and cracks will just flake off, making all your hard work completely useless.

Using an incompatible antifouling paint can do more than just damage your boat—it can also void your manufacturer’s warranty. Always choose a product explicitly labelled as safe for PVC or Hypalon to protect your investment.

When you’re shopping for an antifouling paint for your Easy Inflatables boat, keep an eye out for these specific features:

For owners of high-quality boats, like those made with premium German Valmex PVC, using the right paint is non-negotiable. You’ve invested in a superior material known for its durability and long life; the last thing you want is to undermine that with the wrong chemical cocktail. The right water-based antifouling paint will shield your hull from marine growth without putting the fabric itself at risk.

Remember, antifouling is just one piece of the puzzle when it comes to fabric care. For above-the-waterline protection against UV rays and stains, you can learn more by checking out our guide on using a waterproof spray for fabric. A complete maintenance approach ensures every part of your boat stays in top condition.

Ultimately, choosing a dedicated, inflatable-safe antifouling bottom paint is the only way to get effective protection while preserving the integrity and value of your vessel for years to come.

Picking the right antifouling paint in Australia isn’t a simple one-size-fits-all job. With our massive coastline and incredibly diverse marine environments, what works in one place might be completely useless in another. Your decision really comes down to a few key things: your local water conditions, environmental rules, and how you actually use your boat.

A paint that holds up brilliantly in the cool, temperate waters of Tasmania could fail spectacularly in the tropical, high-growth environment of Queensland. Getting your head around these variables is the first step to choosing a coating that gives you real, lasting protection for your inflatable.

Australia’s waters are incredibly varied, and each type throws a unique challenge at antifouling paint. The biggest factor is the rate of marine growth, which is driven by water temperature, salinity, and nutrient levels.

Tropical Waters (e.g., North Queensland, NT): These warm, nutrient-rich waters are a breeding ground for aggressive marine life. Biofouling happens fast. Up here, you need a high-strength, multi-season ablative paint with a high copper content (or an effective biocide alternative) just to keep up with the constant assault.

Temperate Waters (e.g., Sydney, Melbourne): Marine growth down south is more seasonal. It’s still a significant issue, but the fouling pressure is way less intense than in the tropics. A good quality single-season or multi-season ablative paint is usually more than enough to do the job.

Brackish or Freshwater (e.g., River Systems): These environments see different kinds of growth, often more slime and algae than hard barnacles. Copper-free antifouling paints or biocide-free foul-release coatings can be highly effective and are often a much better choice for the environment.

How you use your boat is just as important as where you use it. The perfect antifouling paint for a boat that lives in the water full-time is completely different from one that’s trailered after every adventure.

Permanently Moored Boats: If your inflatable catamaran or tender stays in a marina berth year-round, you need the most robust protection you can get. A multi-season ablative paint is your best bet, as it wears away consistently to reveal fresh protection without building up thick, heavy layers over time.

Trailered Boats: If you pull your boat out of the water after each use, you likely do not need antifouling paint. The organisms simply don’t have enough time to attach. A simple freshwater rinse is all that’s needed to keep the hull clean.

Boats on Lifts or Dry Racks: For boats stored out of the water for more than a few days at a time, ablative paint is the only viable option. Hard paints oxidise when exposed to air for over 72 hours and lose their punch, whereas ablative paints can be relaunched without any issues.

Environmental rules around antifouling paint are getting stricter all the time. Some states and local marinas have specific regulations about the types of biocides that can be used, so it pays to check first. If you’re looking to hire inflatable boats for a family outing in Australia, the hire company will handle all this for you, ensuring the vessel is compliant and safe.

This is especially true for sensitive ecosystems like the Great Barrier Reef Marine Park. The growing awareness around marine health has spurred major market growth here in Australia. The local antifouling coatings market is set to expand from USD 7.4 billion to USD 12.8 billion between 2025 and 2031, a growth rate that shows just how much demand there is for effective and compliant solutions. You can read more about these Australian antifouling market trends to get a feel for the shifting landscape.

Before you even think about opening a can of paint, it’s absolutely crucial to read its Safety Data Sheet. This document gives you all the essential safety information you need, especially for safe handling and disposal, and lists the personal protective equipment required.

Painting the bottom of your inflatable might feel like a big job, but with the right game plan, it’s something you can definitely tackle yourself. This isn’t about getting a showroom finish; it’s about applying a tough, functional barrier that keeps marine growth off your hull.

Think of it in three simple stages: prep, paint, and patience. Get these right, and you’ll have a coating that works hard all season long.

Here’s a secret every professional painter knows: 90% of a great paint job is in the prep work. This is the most important step, so don’t rush it. The hull needs to be perfectly clean, totally dry, and free from any grease, grime, or old paint that’s starting to flake.

Give the surface a good scrub, then a light scuff-sanding with fine-grit sandpaper. This creates a slightly rough texture for the new paint to grab onto, ensuring it sticks properly.

Before a single drop of paint comes out, get your masking tape on. Use good quality painter’s tape to create a crisp, clean waterline. You’ll also want to carefully mask off the inflatable tubes and the transom—trust me, you’ll be glad you did when you avoid accidental drips and splatters.

Antifouling paint contains some serious chemicals, so your safety is non-negotiable. Always gear up with the right Personal Protective Equipment (PPE). That means solvent-resistant gloves, safety glasses, and a proper respirator mask designed for paint fumes. Work outside or in a very well-ventilated space.

With your boat prepped and protected, you’re ready for the main event. Most antifouling paints made for inflatables go on easily with a small foam roller and a brush. The trick is to apply a couple of thin, even coats instead of trying to slap on one thick layer.

Follow these general steps for a finish that looks and performs like a pro did it:

While doing it yourself can save some cash, it does demand time, patience, and a bit of elbow grease. If you own a high-value boat like an inflatable catamaran, or if you just don’t feel confident tackling the job, calling a marine professional is a smart move.

A pro has the gear and the experience to deliver a flawless result, protecting your investment and giving you total peace of mind. They can also spot and handle any small repairs before painting. Of course, if you’re keen to handle minor fixes yourself, our guide on inflatable boat repairs might come in handy.

Applying antifouling paint is a serious investment in your boat’s performance, but the job isn’t over once the paint dries. Proper maintenance is what really stretches its lifespan, ensuring you get full value from every coat. A simple, routine inspection and cleaning schedule will keep your hull performing beautifully season after season.

Think of your antifouling paint like the tread on a car tyre. You have to check it for wear and tear to know when it’s time for a top-up. After a day on the water, or whenever you have the boat out, take a moment to look over the hull. Check for any signs of thinning paint, scratches, or the first hints of slime and algae. Catching these small issues early prevents bigger fouling problems down the line.

How you clean your painted hull depends entirely on the type of paint you’ve used. This is a critical distinction that can either extend your paint’s life or shorten it dramatically.

Ablative Paints: These coatings are soft by design, wearing away with friction as the boat moves. You should never scrub an ablative paint with a stiff brush or abrasive pad. Doing so literally scrubs the paint—and your money—right off the hull. Instead, use a very soft cloth or sponge with gentle pressure to dislodge any light slime. For many boaties, the boat’s movement through the water provides all the cleaning it needs.

Hard Paints: Hard epoxy paints are much tougher and can handle more rigorous cleaning. You can use a medium-bristle brush or a diver’s cleaning pad to remove any growth without damaging the paint itself. This makes them a better choice if you plan on having your hull cleaned regularly while it’s in the water.

Identifying the right time to reapply is the key to continuous protection. With hard paints, the biocides run out over time even though the paint film itself is still there. If you notice marine growth starting to stick, it’s a clear sign the paint is no longer active and it’s time for a new coat.

Ablative paints give you a much more obvious visual cue. As the coating wears thin, you’ll start to see the underlying primer or previous coat of paint showing through. Some boaties cleverly use a different coloured “signal coat” as their first layer. When you start seeing that different colour peek through, you know without a doubt it’s time to repaint.

This constant need for better solutions has driven huge advancements in antifouling bottom paint. The global market is projected to grow from USD 5.9 billion to USD 13.2 billion by 2031, with modern copper-based paints leading the way thanks to their performance and improved environmental profiles. You can learn more about antifouling market trends on alliedmarketresearch.com.

Setting a realistic maintenance schedule is far better than reacting to a problem. A quick inspection and gentle wipe-down every few weeks can dramatically extend the life of your antifouling paint and save you from a major scraping job later.

For a deeper dive into overall boat care, check out our guide on inflatable boat maintenance made simple. A holistic approach to maintenance will keep your entire vessel in prime condition.

When it comes to antifouling, there are always a few questions that pop up. To help you get it right the first time, we’ve put together a list of the most common queries we get from Australian boaters.

Almost certainly not. Antifouling paint is designed for one job: protecting boats that live in the water for long stretches. If you pull your boat out after every adventure and pop it on a trailer, a good rinse with fresh water is all you need to stop any growth from taking hold. Spending money on antifouling would be an unnecessary expense.

It is strongly recommended that you do not apply antifouling paint to the inflatable tubes. These paints are packed with chemicals that are great for deterring marine life but can be seriously harmful to PVC or Hypalon fabric over time. The best approach is to paint only the rigid hull or transom below the waterline and give the tubes a regular clean to keep them looking sharp.

How often you need to repaint really comes down to the paint you choose, how much you use your boat, and the water conditions in your local spot.

Keep in mind, though, that high-growth areas like North Queensland will demand more frequent repainting than the cooler southern waters of Tasmania. The best way to know for sure is to keep an eye on your hull.

Here’s a great pro tip for ablative paints: use a different colour for your first coat. When you start seeing that “signal coat” peeking through, you know it’s definitely time to repaint. No guesswork needed!

Yes, it absolutely can. Using a paint that isn’t specifically made for inflatable boats can cause the fabric or seams to break down. This kind of chemical damage is almost never covered by a manufacturer’s warranty, turning a simple paint job into a very costly mistake.

To protect your investment in an Inflatable Catamaran or any other quality inflatable, always go for a high-quality, water-based paint that is clearly labelled as safe for PVC or Hypalon. If you’re ever in doubt, chat with a marine professional or give our support team a call for advice.

Are you trying to compare prices and features of inflatable boats in your area? At Easy Inflatables, we can help. We have the best inflatable boats for recreational use available near you, with a wide range of Inflatable Catamarans and boats perfect for any Australian adventure. Whether it’s for a family outing or a serious fishing trip, we have the right options. Compare prices and features on our site today. https://easyinflatables.com.au

Experience the ultimate freedom on the water with our top-quality inflatable boats and accessories. Easy Inflatables is your trusted partner, providing everything you need for a safe and unforgettable adventure.

At Easy Inflatables, we believe in empowering adventurers with high-quality inflatable solutions. Our commitment to durability and performance ensures that every product enhances your outdoor experiences.