If you’ve spent any time on the water, you know the fight against rust is relentless, especially for your trailer and boat’s metal parts. An anti-rust spray is your first line of defence—a protective coating that creates a tough barrier against the moisture and salt that wants to eat away at your gear. For owners of the best inflatable boats for recreational use, it’s an absolute must-have for protecting aluminium transoms, outboard motors, trailers, and even the smallest fasteners from the harsh Australian saltwater environment. Whether you have an inflatable boat or a popular inflatable catamaran, this is a crucial maintenance step.

That perfect family outing on the water in Australia can leave a lasting, unwanted mark on your equipment. It’s a brutal combination: intense sun, high humidity, and corrosive saltwater all ganging up on your vessel’s metal components. The battle begins the moment your trailer hits the boat ramp.

This constant environmental assault doesn’t just target cheap steel; even high-quality, marine-grade aluminium and stainless steel will eventually fall victim. Without a protective barrier, these materials will start to show pitting, galvanic corrosion, and ugly surface rust. Comparing prices and features of anti-rust sprays in your area can help you find the best options to prevent this damage.

Ignoring those first hints of rust can lead to some serious headaches that go way beyond just looking bad. A small patch of rust on a trailer spring or a bit of bubbling paint on an outboard bracket is often just the tip of the iceberg.

If you let it go, you’re looking at much bigger problems:

A proactive approach is always better than a reactive repair. Treating rust prevention as a core part of your maintenance routine, rather than an afterthought, is the key to preserving the safety and value of your entire setup.

The scale of this issue is massive. Australia’s anti-corrosion coatings market was valued at a staggering USD 1.04 billion in 2024, a figure driven by the non-stop need to protect metal structures in our harsh marine environments.

Using a quality anti-rust spray isn’t just about keeping your boat looking sharp. It’s about protecting your investment, ensuring your gear is reliable, and making sure your vessel is always ready for your next adventure. Our range of corrosion protection products can help you get started.

Walking down the aisle for an anti-rust spray can be a bit daunting. It’s tempting to just grab a standard can from your local auto shop, thinking it’ll do the job. But here’s the reality: those products are designed for road grime and rain, not the relentless assault of a saltwater environment.

To really protect your investment, you need a formula specifically engineered for marine life. These sprays contain much more robust inhibitors that create a durable, water-repellent barrier. The right choice really comes down to what you’re protecting and how you use it. For instance, the protection needed for an inflatable catamaran trailer might differ from a smaller tinny’s trailer.

Not all marine coatings are created equal. Different formulas offer unique advantages, and thinking about the specific job will help you nail the right product for the right part of your boat or trailer. If you’re looking to compare prices and features of anti-rust sprays available near you, understanding these types is the first step.

To make it easier to see the differences, here’s a quick comparison of the most common types you’ll find.

Each spray type has its sweet spot. A lanolin spray that’s perfect for your outboard’s wiring might not be the best choice for a trailer frame that gets dunked in saltwater every weekend. This table breaks down the pros and cons to help you match the product to the part.

| Spray Type | Best For | Pros | Cons |

|---|---|---|---|

| Lanolin-Based | Outboard cowlings, electrical connections, steering cables, moving parts. | Creates a waxy, self-healing film. Excellent moisture displacement. Non-conductive. | Can attract dirt. May need more frequent reapplication on high-wear surfaces. |

| Polymer & Ceramic | Painted surfaces, polished metals, hulls where a clean finish is desired. | Forms a hard, slick barrier. Repels water and contaminants effectively. Long-lasting shine. | Requires very clean surface for proper bonding. Can be more expensive. |

| Epoxy | Trailer frames, axles, high-impact areas, underwater components. | Creates a tough, permanent coating. Exceptional resistance to abrasion and chemicals. | Difficult to remove. Requires significant surface prep. Not flexible. |

Ultimately, the best approach is often using a combination of products. Epoxy for the heavy-duty trailer parts, polymer for the outboard’s painted surfaces, and lanolin for all the little bits and pieces that need to keep moving freely.

Beyond the base formula, a few other things are critical when you’re comparing cans.

First, look for explicit saltwater resistance on the label. This is non-negotiable for any marine application. Second, check for UV stability. The harsh Australian sun can cook weaker coatings right off, leaving your metal exposed and vulnerable in no time.

Finally, think about compatibility. Some aggressive solvents can harm your inflatable boat’s fabric. Always double-check that the spray is safe for incidental contact with PVC or Hypalon. Protecting your metal shouldn’t come at the cost of damaging your tubes.

Of course, protecting the tubes themselves is a different game entirely. For that, you’ll want to check out our guide on finding the right waterproof spray for fabric.

The difference between an anti-rust spray coating that lasts a full season and one that flakes off in weeks almost always comes down to the prep work. Honestly, rushing this stage is the number one mistake boat owners make. A truly effective barrier needs a surface that is perfectly clean, dry, and ready for the coating to grab onto.

This is about more than just a quick wipe-down. Salt, in particular, is a massive problem. Even after drying, microscopic salt crystals hang around, attracting moisture from the air and creating the perfect breeding ground for rust right under your new protective layer. Think of it like trying to paint a dusty wall—the paint just sticks to the dust, not the wall itself, and will eventually peel away.

Different parts of your boat and trailer demand slightly different approaches. What works for a painted outboard motor bracket isn’t necessarily the best method for a galvanised trailer frame.

A thorough freshwater wash is your universal first step. Pay extra attention to your aluminium transom and outboard motor brackets, making sure you flush out every nook and cranny where salt might be hiding.

Next up, you need to degrease. Engine oils, exhaust residue, and even sunscreen can leave a thin, invisible film that will completely ruin the adhesion of your anti-rust spray.

The goal is to achieve what the pros call a “water break-free” surface. This means when you rinse it with fresh water, the water sheets off smoothly instead of beading up. Beading is a dead giveaway that oil or other contaminants are still present.

If you’ve already spotted some light surface rust, you’ll need to get rid of it before spraying. A non-metallic scouring pad or a plastic-bristle brush is often enough to remove the loose material without gouging the metal underneath. You’ll want to avoid aggressive wire brushes on aluminium or galvanised parts, as they can strip away the very protective layers you’re trying to save.

For more stubborn issues, learning some basic techniques can be a lifesaver. You might be interested in our guide on inflatable boat repairs for further tips on maintenance and upkeep.

Once cleaned and degreased, the final step is ensuring the surface is bone-dry. Trapped moisture is the absolute enemy of any protective coating. Let it air dry completely in the sun if you can, using a clean, dry cloth to wipe down any stubborn water spots. Only when the surface is clean, dull, and completely dry is it ready for your anti-rust spray.

With a perfectly prepped surface, you’re ready for the most satisfying part of the job—applying the anti rust spray. This is where your attention to detail really pays off, creating a tough protective shield that will last for months.

The secret to a professional, long-lasting finish isn’t a thick, heavy coat. It’s all about technique and control.

The best approach is to apply several light, even coats rather than one thick one. This method is the key to preventing runs, drips, and uneven curing, which ensures a consistent, tough barrier. Think of it like spray painting a piece of furniture—you build up the colour slowly with thin layers for a perfect result.

First things first, shake the can vigorously for at least a minute. You need to make sure all the protective agents are fully mixed before you start spraying.

When you begin, hold the can about 20-30 centimetres from the surface and use a smooth, sweeping motion. Overlap each pass by about 50% to guarantee you get complete coverage without creating thick spots.

This technique is especially critical for complex components like an outboard’s tilt and trim mechanism or the intricate parts of a steering linkage. Multiple light passes let you work the spray into every nook and cranny without flooding sensitive areas.

Pro Tip: Keep the can moving at all times. Pausing in one spot, even for a second, is the fastest way to cause drips and create a weak point in the coating. A continuous, steady hand is the key to a flawless finish.

Before you get spraying, it’s a smart move to protect the parts you don’t want to coat. Overspray is inevitable, and some formulas can stain or damage your inflatable boat’s tubes. Use painter’s tape and plastic sheeting to mask off the PVC or Hypalon fabric right next to the transom. This simple step saves a mountain of cleanup and prevents any accidental damage.

Some parts of your boat and trailer are just plain awkward to coat properly, yet they’re often the most vulnerable to rust. Here’s how to tackle them.

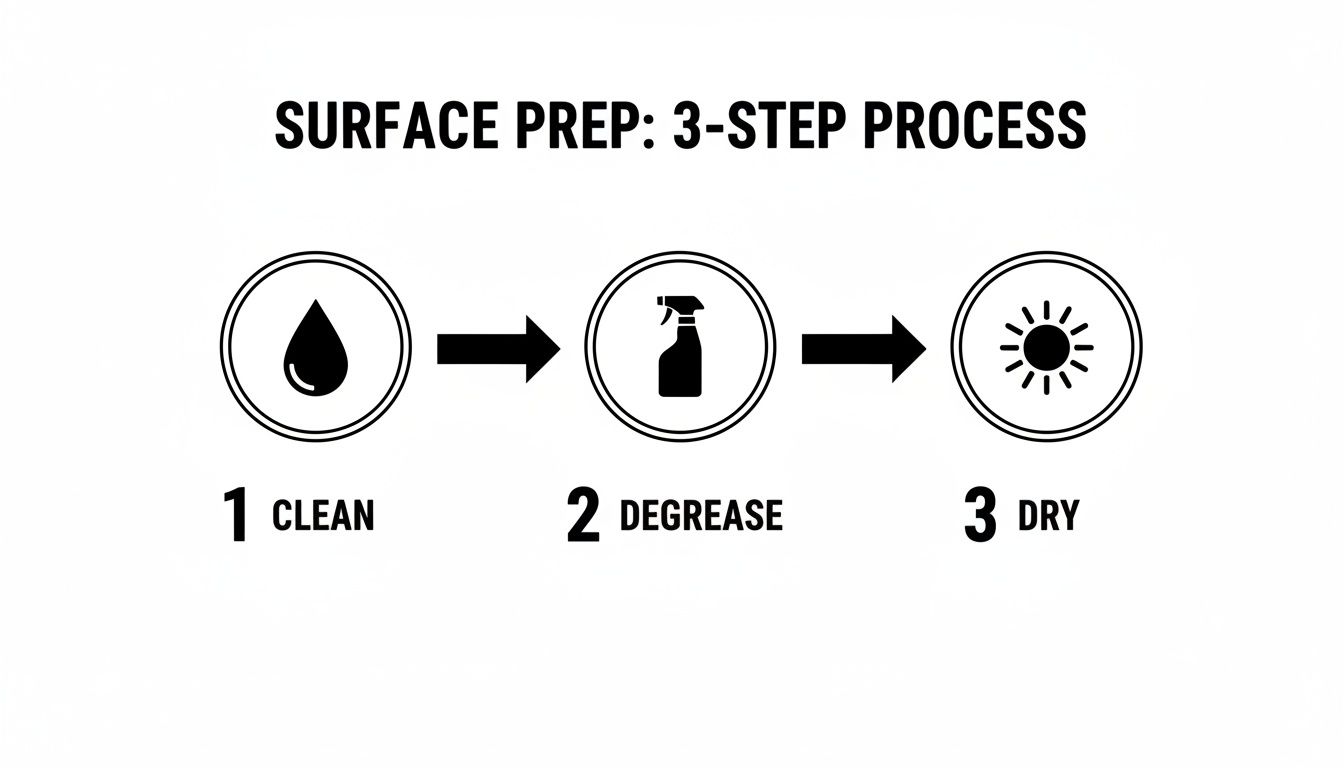

Proper surface preparation is the foundation for a successful application, ensuring the spray adheres directly to the metal and forms a strong, lasting bond. This simple visualisation shows the three essential steps.

Once applied, just follow the product’s instructions for drying times. Most sprays are touch-dry within an hour, but it can take up to 24 hours to cure fully. Try to avoid getting the surface wet during this period to ensure you get maximum durability.

Properly applying an anti-rust spray is a core skill for any boat owner, but for other common issues, you might want to learn more about general rubber boat repair.

Let’s be honest, rust prevention isn’t a one-and-done job you can tick off a list. It’s an ongoing commitment, a habit that becomes a core part of looking after your boat. The trick is to create a simple, realistic maintenance schedule that doesn’t feel like a chore, safeguarding your investment year after year without getting overwhelmed.

How often you need to do this really comes down to your boating habits. If you’re an avid angler launching into saltwater every weekend, you’ll need a much more rigorous schedule. On the other hand, if you’re only taking the boat out on a freshwater lake occasionally, your reapplication timeline can be a lot more relaxed. If you plan to hire inflatable boats for a family outing in Australia, you’ll notice the best companies meticulously maintain their equipment this way.

Consistency is your absolute best defence against corrosion. A quick visual inspection after each trip can help you spot issues long before they turn into expensive repairs. Just think of it as a five-minute debrief for your boat and trailer once you’re back on dry land.

Here’s a simple checklist you can run through:

A proactive mindset is crucial. Catching a small rust spot on a trailer spring and treating it immediately takes only a few minutes. Ignoring it can lead to a complete spring failure down the track.

For the best results, remember that rust prevention is just one piece of the puzzle. It fits into a larger comprehensive boat maintenance checklist that is essential for keeping your entire vessel in top shape.

A good rule of thumb for frequent boaters in coastal areas is a full reapplication every six months. If you’re in a less harsh, freshwater environment, an annual application is often more than enough. It’s a small price to pay for long-term protection.

The demand for this level of protection is growing fast right across Australia. The country’s corrosion protective coatings market, valued at USD 1,123.2 million in 2025, is projected to hit USD 1,581.5 million by 2032. This growth shows just how important robust solutions are in our tough marine and industrial environments.

By weaving these simple checks into your regular routine, you can turn corrosion prevention from a massive project into a series of small, manageable tasks. For more tips on keeping your vessel in top condition, check out our guide on how inflatable boat maintenance is made simple.

Even with the best instructions, a few questions always pop up when you’re tackling a new maintenance job. Let’s run through some of the most common ones we hear from boat owners, so you can protect your gear with total confidence.

Look, it’s definitely better than using nothing at all. But a standard automotive anti-rust spray just isn’t cut out for the long haul in a marine environment.

Car products are designed to fend off road grime and the odd rain shower, not repeated dunks in corrosive saltwater. A marine-specific formula—whether it’s lanolin, a polymer sealant, or even bituminous paint—contains much beefier inhibitors. It creates a far more durable, water-repelling barrier that will give you massively better, longer-lasting protection.

This is a great question and a very real concern. Some of the more aggressive, solvent-heavy sprays absolutely can stain, soften, or even damage the PVC or Hypalon fabric of your tubes. This is exactly why careful masking is so critical.

Always take those few extra minutes to properly cover your tubes with painter’s tape and plastic sheeting before you get started.

To play it extra safe, stick to products that are specifically labelled “safe for plastics and rubbers.” Most high-quality lanolin and silicone-based sprays fall into this category. If you’re ever in doubt, just do a quick spot test on a small, hidden area of the tube fabric first.

Getting all that loose, failed coating off is non-negotiable. You need a clean surface for the new layer of anti-rust spray to grab onto properly. A strong bond means protection that actually lasts.

Start with a stiff plastic brush or a non-metallic scraper to gently chip away all the flakes. You’ll want to avoid using a steel wire brush, especially on aluminium or galvanised surfaces—it can easily scratch right through the protective finish you’re trying to save.

Once the loose stuff is gone, give the area a good clean with a marine degreaser, rinse it thoroughly with fresh water, and let it dry completely before you even think about applying the new coat.

Yes, 100% yes. In fact, this is probably one of the most important—and most overlooked—steps in proper trailer maintenance. Box-section trailer frames are notorious for trapping saltwater, letting them rust from the inside out. You often won’t see the damage until it’s way too late.

Most quality anti-rust spray cans come with a long, thin extension nozzle for this exact reason. Use it to spray generously inside all the frame openings and drain holes. Getting a good coat on those internal surfaces is the only way to stop hidden rust dead in its tracks.

Ready to protect your investment and spend more time on the water? Explore our complete range of marine maintenance and boating solutions at Easy Inflatables. We have everything you need to keep your inflatable boat, inflatable catamaran, and trailer in top condition. Shop now at Easy Inflatables.

Experience the ultimate freedom on the water with our top-quality inflatable boats and accessories. Easy Inflatables is your trusted partner, providing everything you need for a safe and unforgettable adventure.

At Easy Inflatables, we believe in empowering adventurers with high-quality inflatable solutions. Our commitment to durability and performance ensures that every product enhances your outdoor experiences.