A bilge pump float switch is the simple, automatic trigger that tells your bilge pump when to turn on. Think of it as your boat’s personal lifeguard—a small, unassuming device that stands between a dry bilge and a potential disaster, working tirelessly even when you're not on board.

Picture this: you’ve just docked your boat after a perfect day on the water. Overnight, a heavy downpour starts, or a small, slow leak develops from a loose fitting. Without a reliable automated system, that tiny issue could quickly become serious water damage or, in a worst-case scenario, a swamped vessel.

This is where the true value of a bilge pump float switch becomes crystal clear. It's your first line of defence against any unexpected water getting in. It instantly transforms your manual bilge pump into a fully automated, 24/7 monitoring system that doesn't need you there to flip a switch. It just reacts to the rising water, offering constant protection and complete peace of mind.

The main job of a float switch is automation. It makes sure your bilge pump kicks in exactly when it's needed, stopping small amounts of water from building up into a major problem. This automated response is critical for a few key reasons:

For instance, a tiny, unnoticed drip from a cooling hose could let in several litres of water per hour. Over a full day, that's a serious threat. A working float switch will detect this rise in minutes, turn on the pump, clear the water, and switch off—repeating the cycle as needed to keep your boat safe and sound.

A correctly installed and maintained bilge pump float switch is arguably one of the most important safety devices on any boat. Its failure is a common factor in swamping and sinking incidents, making regular checks an absolute must.

While the convenience of an automatic system is great, its role in safety is what really matters. It acts as a vital backup, especially when you’re away from the helm or off the boat completely. This proactive approach is a core part of responsible seamanship.

Understanding and looking after this small but mighty device is a key part of keeping your vessel prepared for anything. To learn more about other critical safety measures, check out our articles on essential boat safety. The bilge pump float switch is just one piece of the puzzle, but it’s a crucial one in the larger system designed to protect you, your passengers, and your boat.

Think of a bilge pump float switch as a simple, automatic light switch for your pump. But instead of you flipping the switch, rising water does all the work. It’s a beautifully simple mechanical process that relies on one of nature’s most basic principles: buoyancy. This is what makes it an incredibly reliable system that protects your boat without needing any complex electronics or constant babysitting.

The whole operation is a straightforward chain of events. Water finds its way into the bilge—whether from rain, a small leak, or just spray over the side. As the water level creeps up, it lifts a buoyant float inside the switch. This float is connected to an internal lever, which is the trigger for the whole show.

Once the water lifts the float to a specific, pre-set height, the lever inside the switch housing pivots. This is the critical moment; that simple movement flips a small electrical switch from "off" to "on". Just like that, it completes an electrical circuit, letting 12V or 24V power flow from your battery straight to the bilge pump, kicking it into action instantly.

The pump gets to work, clearing the water out of the bilge. As the water level drops, so does the float. When the bilge is nearly empty, the float settles back into its resting position. This causes the lever to flip the switch back to "off," cutting the power and shutting the pump down. Mission accomplished.

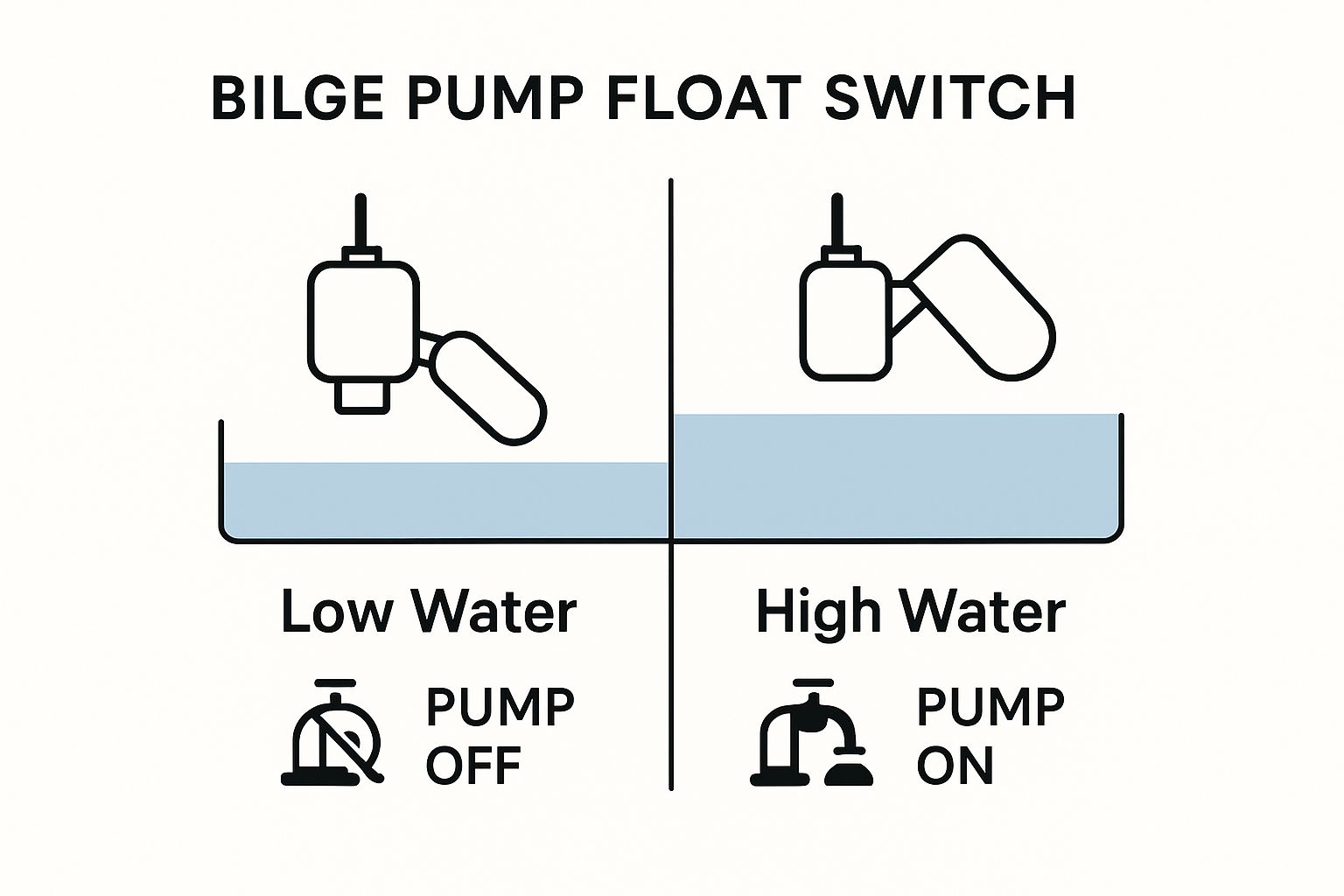

This infographic breaks down the two key states of a bilge pump float switch.

You can see the direct relationship between the water level and the pump kicking on. It's the core principle that makes this automatic safety device so effective.

If that's still a bit technical, imagine a little see-saw down in your bilge. One end has a float, and the other end is pointing at a big red "ON" button for your pump.

This simple cause-and-effect action is what makes the float switch so bulletproof. There are no fancy sensors to fail or software to crash; it’s just pure, reliable mechanics doing their job.

For total peace of mind, a float switch is almost always wired to a three-position panel switch at the helm, usually labelled AUTO-OFF-MAN. This setup gives you the best of all worlds.

It's standard practice to wire the automatic float switch circuit directly to the battery (with an inline fuse), bypassing the main battery isolator switch. This is critical because it ensures your bilge pump has power and can activate even when you've turned off all the other electronics on your boat.

While this automatic system is fantastic, it never hurts to know your other options. For smaller boats or as a secondary line of defence, you might also want to look into the different kinds of manual bilge pumps and how they work. Understanding this simple yet vital mechanism is the key to keeping your boat safe and dry.

Picking the right bilge pump float switch isn’t a one-size-fits-all job. The best choice really comes down to your boat, the size and shape of your bilge, and how you use your vessel. It’s a small bit of gear, but it’s responsible for running a critical safety system automatically, so getting it right is crucial. Think of it like choosing the right tyres for your car—what works for a city runabout isn't going to cut it on a rugged off-road track.

This guide will walk you through the options to find the perfect match for your needs. We'll compare the most common types and break down the technical details that actually matter, so you can be confident your choice will deliver reliable performance for years to come.

Your first big decision is the type of switch mechanism. Each one has its own strengths and is suited to different bilge environments. A cramped, debris-prone bilge in a small fishing tinnie has very different needs than the clean, open bilge of a larger cruiser.

There are three main types you'll come across:

To make the choice easier, here's a quick breakdown of how they stack up against each other.

| Switch Type | Operating Principle | Best For | Potential Drawbacks |

|---|---|---|---|

| Lever-Style | A hinged float physically lifts a lever to activate the switch. | Clean, open bilges with minimal debris. | The exposed float can be easily jammed by debris. |

| Protected/Caged | Same as a lever switch, but the float is inside a protective cover. | Bilges prone to collecting leaves, wiring offcuts, or other small debris. | Can be slightly bulkier than uncaged models. |

| Solid-State | Electronic sensors detect water and trigger a circuit. No moving parts. | Any bilge, especially tight spaces or where ultimate reliability is needed. | Higher initial cost and can be sensitive to oil or sludge. |

Ultimately, a protected switch offers a great balance of cost and reliability for most boaters, while a solid-state switch is the premium choice for anyone who wants a true set-and-forget system.

Once you’ve settled on a type, you need to check the technical specs. Mismatching these details with your pump or boat's electrical system is a common mistake that can lead to a burnt-out switch or even a fire risk.

A float switch’s amperage rating is its most critical specification. If the switch isn't rated to handle the power your pump draws when it starts up, it will burn out quickly, leaving your boat unprotected. Always choose a switch with an amp rating higher than your pump's maximum draw.

Here are the essential things to check:

With a growing focus on marine safety, these devices are now standard equipment on most boats. The global market for bilge float switches is expected to grow, with 24V systems leading the charge due to their use in larger vessels. Here in Australia, where maritime safety is a top priority, fitting a reliable float switch is a sensible and often mandatory step for all boat owners.

Making the right choice goes beyond just the switch; it's about building a complete safety system. Think about pairing your new switch with other valuable gear. For more ideas on outfitting your vessel, check out our guide on essential inflatable boat accessories. A well-chosen switch is the heart of your automatic bilge system, so taking a bit of time to select the right one is a decision that pays off in safety and peace of mind.

A top-quality bilge pump float switch is only as good as its installation. Getting this right is the difference between a reliable, automatic safety net and a disaster waiting to happen. This guide will walk you through the job with clear, practical steps, making sure your silent guardian is perfectly positioned and wired for duty.

Before you even think about picking up a tool, the first step is always safety. The bilge pump circuit is often wired straight to the battery, meaning it’s live even when your main battery switch is off. You absolutely must disconnect the power source to avoid any risk of electric shock.

Safety First: Disconnect All Power. Head to your battery compartment and disconnect the negative (black) cable first, then the positive (red). This simple act is the non-negotiable first step for any marine electrical work.

With the power safely off, you can now focus on the most important part of the physical install: finding the perfect spot.

Where you place your float switch determines how well it can protect your boat. The aim is to mount it where it will sense rising water as early as possible, but without being falsely triggered by normal sloshing or getting jammed by debris.

Your first job is to find the lowest point in the bilge. Water always finds its way here, so putting the switch in this spot ensures it kicks in before the water level becomes a real problem. It also needs to be mounted perfectly level so the float mechanism can move freely and accurately, just as it was designed.

But finding the lowest point is only half the battle. You also have to look at what’s around it.

Once you’ve scouted the perfect location, secure the switch firmly to the hull or a mounting bracket using stainless steel screws. A loose switch is an unreliable switch.

Proper wiring is what brings your automated system to life. The standard—and safest—way to wire everything is through a three-way panel switch, usually labelled AUTO-OFF-MANUAL. This setup gives you total command over your bilge system. You’ll need to use high-quality, marine-grade tinned copper wire, which is made specifically to fight corrosion in the harsh saltwater environment.

Here’s the basic wiring process:

Every connection should be made using marine-grade butt connectors and sealed with heat-shrink tubing. This locks out moisture and prevents corrosion, which is the number one enemy of marine electrical systems. This dual-pathway wiring gives you both a dependable automatic system and a manual backup for peace of mind. For a deeper look into onboard safety systems, our guide on inflatable boat setup tips for safety offers more valuable insights.

Even with a perfect installation, the harsh marine environment will eventually put your bilge pump float switch to the test. When your automated system starts acting up, it’s easy to feel a bit of stress, but don't panic. Most issues are surprisingly simple to diagnose and fix with a bit of logical thinking, turning a potential crisis into a manageable job.

This guide walks you through the three most common failure scenarios boaties face: the pump that won't turn on, the one that won't turn off, and the one that cycles erratically. By following a clear checklist for each problem, you can quickly find the culprit and get your boat’s most important safety system back online.

This is the one that really gets your attention. You see water in the bilge, but the pump is sitting there, silent. Before you assume the worst, work through these simple checks, starting with the most likely offenders.

Manually Test the Switch: The quickest test is to simply reach into the bilge and carefully lift the float lever by hand. If the pump immediately kicks on, the switch itself is working fine. The problem is likely that the water level just hasn't hit the activation point yet, or maybe the switch is mounted a touch too high.

Check for Obstructions: If you lift the float and still nothing happens, have a look to see if something is physically jamming it. Bilge debris like leaves, bits of fishing line, or stray cable ties are notorious for getting lodged under the float, stopping it from rising with the water.

Inspect Fuses and Wiring: If the float moves freely but the pump remains lifeless, it's time to check the electricals. Start by finding the inline fuse for the float switch circuit—it's usually near the battery. If the fuse is blown, replace it and test again. If it blows a second time, you've got a short circuit somewhere that needs a proper investigation.

A pump that runs continuously isn't just annoying; it’s a serious drain on your battery. This issue, often called "running on," almost always points to a problem with the switch or its immediate surroundings.

A constantly running pump is often caused by the float switch being stuck in the 'on' position. This can happen due to debris lodging under the float after it has been activated, or internal failure of the switch mechanism itself.

A common culprit is a small amount of water sloshing around, constantly re-triggering the switch. But if the bilge is dry and the pump is still humming away, your switch is likely stuck. This could be due to grime building up inside the switch housing or a simple mechanical failure. Sometimes, a gentle tap on the switch housing can free it up, but a permanent fix often means cleaning it out or replacing it altogether.

Globally, user reports and marine forums make it clear that float switch failures—from sticking on or off to completely reversing their function—are not uncommon. Industry experts reckon that the lifespan of a typical bilge float switch in harsh marine environments, like those common in Australian waters, is anywhere from 2 to 5 years, depending on its quality and how well it's been looked after. You can find more insights about these common failures from fellow boaters.

If your pump seems to have a mind of its own, cycling on for a few seconds at a time even when you're tied up in a calm marina, the cause is often "water-logging" or an electrical gremlin.

By methodically working through these diagnostic steps, you can confidently troubleshoot most common float switch issues. This practical know-how means you can make an informed repair, restoring your system's reliability and your peace of mind on the water.

When it comes to a bilge pump float switch, the best way to fix a problem is to make sure it never happens in the first place. This isn't about spending hours with a toolbox in a cramped bilge; it's about a simple, repeatable routine that keeps your boat’s silent guardian ready for duty.

Think of it as a five-minute investment that pays massive dividends in safety and peace of mind. A well-maintained switch is a dependable one, giving you the confidence that your automated bilge system will kick in exactly when you need it. A little effort now helps you avoid the common failure points that can lead to big, expensive problems later.

The secret to long-term success is building a quick check into your regular boating routine. Before you head out, and at least once a month, run through this simple but incredibly effective list. It’s designed to catch small issues before they snowball.

This routine quickly becomes second nature and is a core part of responsible boat ownership. A few moments spent here can save you a world of stress and potential damage down the track.

Manual Float Test: This is the most critical check. Simply reach down and carefully lift the float lever. You should hear the pump kick in instantly with a healthy hum. Let it go, and the pump should shut off cleanly. This one action confirms the switch, the wiring, and the pump are all talking to each other correctly.

Clear Out Debris: The bilge is where dirt, leaves, stray fishing line, and other gunk naturally collects. Take a moment to clear anything from around the switch and the pump intake. This is crucial, as a jammed float is one of the leading causes of switch failure.

Visual Wiring Inspection: Have a good look at the wires connected to both the switch and the pump. You’re looking for the first signs of corrosion—that tell-tale greenish-white powder that forms on terminals. Also, check that all connections are snug and the wires are securely fastened, not dangling where they can chafe or snag.

To take things a step further, you can add a couple of extra steps to your seasonal maintenance schedule. These small actions help fight back against the harsh marine environment.

A regular freshwater rinse of the bilge and the float switch can work wonders. Over time, salt crystallisation and grime build-up can make moving parts sticky. A quick wash-down helps keep the mechanism free and responsive.

After cleaning the electrical connections, consider applying a light coat of a moisture-displacing lubricant. This adds an extra layer of protection against the damp, corrosive atmosphere lurking in the bilge. Following a consistent checklist is one of the pillars of good boat maintenance practices.

Here in Australia, the consequences of a failed float switch can be severe, impacting our massive community of recreational and commercial boaties. While official failure stats aren't centrally tracked, it's clear from local marine forums that switch reliability is a constant concern for Aussies on the water. This just highlights why taking personal responsibility for maintenance is so crucial for every single boat owner.

At Easy Inflatables, we believe that safety and reliability are the cornerstones of a great day on the water. A dependable bilge pump system is non-negotiable, and our range of high-quality boats and accessories are designed to give you peace of mind. Explore our expertly crafted inflatable boats and find the perfect setup for your next adventure at https://easyinflatables.com.au.

Experience the ultimate freedom on the water with our top-quality inflatable boats and accessories. Easy Inflatables is your trusted partner, providing everything you need for a safe and unforgettable adventure.

At Easy Inflatables, we believe in empowering adventurers with high-quality inflatable solutions. Our commitment to durability and performance ensures that every product enhances your outdoor experiences.